Injection & Assembly

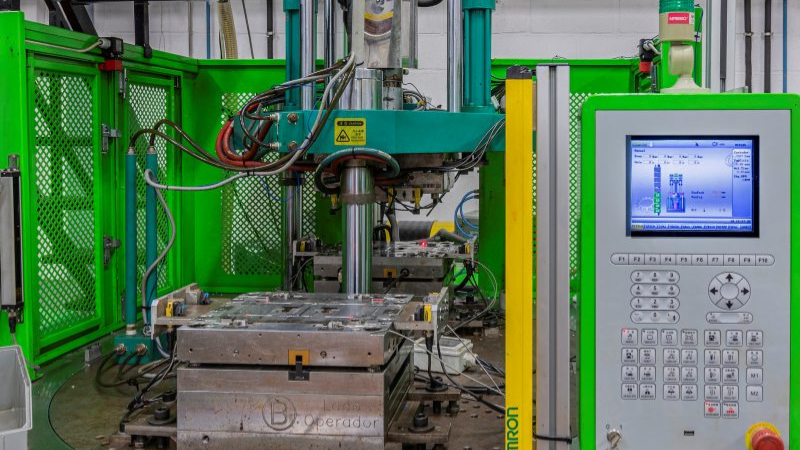

With a production facility equipped with 47 injection machines, Vipex offers complete solutions for molding technical plastic parts. We master different injection technologies, including:

- Single-Material Injection: For parts made from a single material, ensuring high dimensional stability.

- Multi-material Injection: Combination of distinct materials in the same cycle, ensuring greater functionality and design.

- Overmolding: Coating or integrating components for reinforcement or aesthetic enhancement.

- ISBM – Injection-Stretch-Blow Molding: Technology used for the production of high-precision hollow parts.

Production planning is supported by integrated management software, optimizing all stages of the process and ensuring efficiency, on-time delivery, and consistent quality.

In assembly, we provide a complete service — from component integration to the final packaged product. We operate manual lines supported by automation techniques for quality control and error reduction, as well as fully automated and robotic lines, ensuring consistency, efficiency, and strict adherence to deadlines.